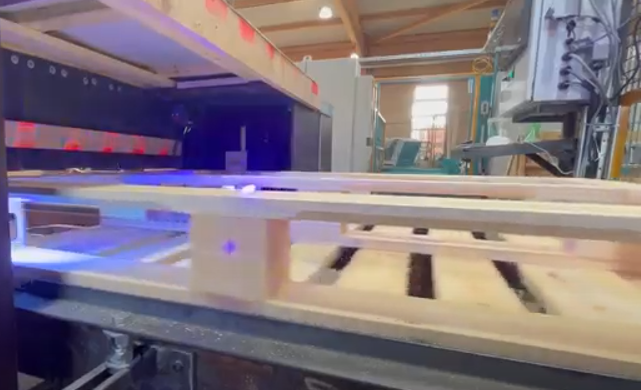

Schlesselmann meets high standards when it comes to marking. They are happy to tell why they decided to use Photon-Jet for printing their pallets.

What exactly was Schlesselmann looking for in a printing installation?

For a long time we were looking for a solution to reliably and legibly print our pallets with. One that can be changed quickly and flexible and works well on fresh and dry wood. Especially when printing fresh wood with very different moisture levels, the tests with many of the techniques that we tried reached their limits.

Why did you choose Photon-Jet?

We produce a large number of different pallets for our customers, which means that they need to be changed or converted quickly and flexibly. Our customers place high demands on the quality of Schlesselmann wooden pallets. After all the trials and above all after talks with experienced users of PhotonJet, we decided on this technology. We haven’t found anything better on the market.

What kind of system was used before?

We used both classic burning stations with branding stamps as well as oil based printers.

How did the installation of the G4I printing systems go?

The installation went smoothly. The preparation between G4I and our technology department was good.

What can you tell about the G4I support in installation?

All employees who are involved in the prining systems have been trained and instructed directly by G4I. After that, no questions arose in practice.

Schlesselmann is a fourth-generation, family-run company with around 60 employees and belongs to the HPE CERTIFIED PALLETS specialist group.